Maintaining quality during the pomace drying procedure in fertilizer production requires careful control over raw materials, moisture reduction techniques, and equipment selection. Pomace fertilizer making represents a systematic process where the balance between water content, nutrient retention, and granulation efficiency becomes the key to producing stable organic particles. When manufacturers focus on proper pomace dehydration, the entire fertilizer production system gains consistency, durability, and higher market value.

What Types of Raw Materials Enter the Pomace Fertilizer Production Process?

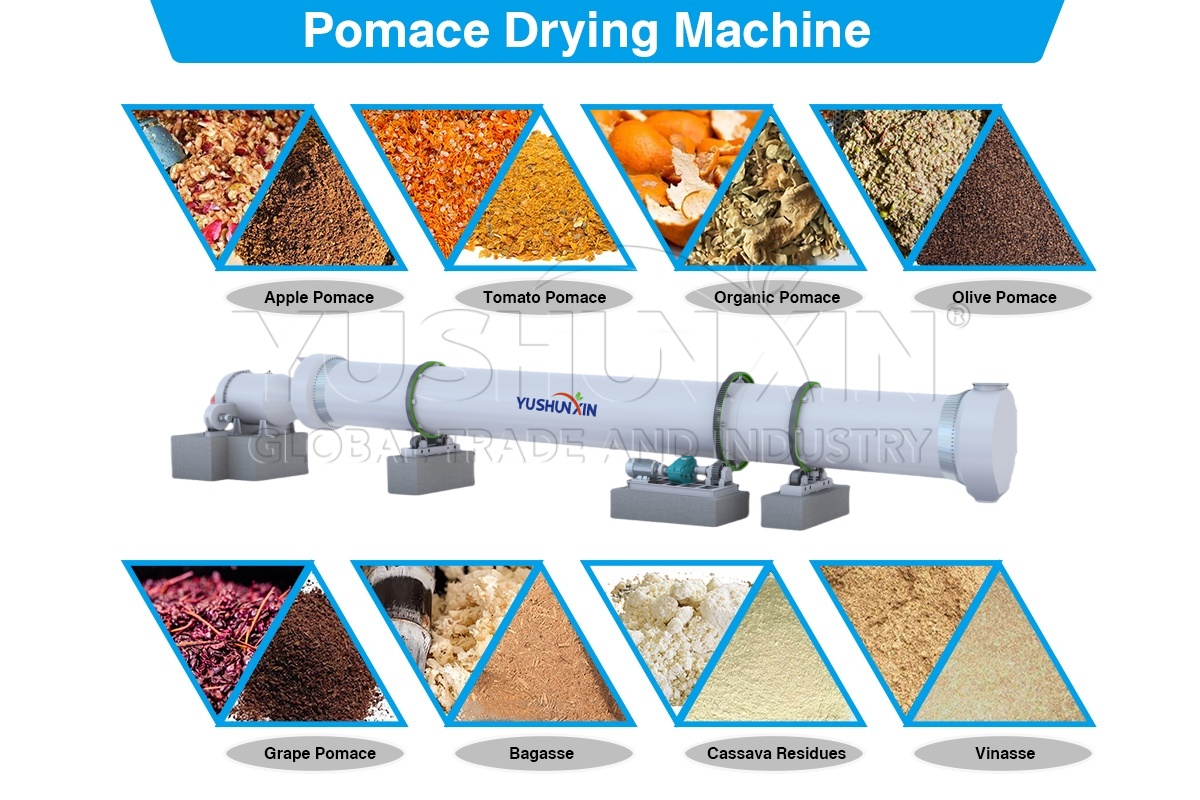

Different industries generate high-moisture organic waste, which becomes valuable raw material for fertilizer manufacturing. Fruit juice factories, wineries, and vegetable processing plants produce large amounts of fruit pomace, grape pomace, or vegetable residues with more than 85–90% water content. This kind of raw material requires proper drying before composting and granulation.

Fruit pomace contains sugar, fiber, and nutrients that improve the structure of organic fertilizer. Grape pomace carries tannins and minerals that can enrich compost-based fertilizer. Olive pomace introduces oils and micronutrients that can support soil fertility when processed correctly. Vegetable pomace contributes nitrogen-rich materials that balance carbon-heavy feedstocks during the compost procedure. Each type of pomace waste brings different benefits, but every industry faces the same challenge: efficient water reduction to make the material suitable for fertilizer granulation and long-term storage.

How Does Moisture Reduction Influence Fertilizer Production Quality?

The water content of pomace directly affects the efficiency of the fertilizer production procedure. If moisture stays above 70–80%, the composting stage develops anaerobic conditions, which lowers quality, produces odor, and delays granulation. Proper dewatering and drying lower the risk of nutrient loss and ensure stable particle formation during the pelletizing stage.

A complete pomace processing system usually includes four levels of water reduction. First, a dewatering machine reduces excessive free water quickly. Second, a compost turner manages aerobic composting, which naturally removes part of the internal moisture. Third, a wet granulator or pelletizer shapes the semidry material into fertilizer granules while still controlling internal water levels. Finally, a pomace dryer reduces the remaining moisture to around 10% or below, guaranteeing that every fertilizer granule achieves stability, hardness, and storage safety. Each stage ensures that the pomace fertilizer maintains strong structure and long shelf life, which creates higher acceptance in the agricultural and landscaping industries.

Why Does the Pomace Dryer Become the Key Machine in Fertilizer Making?

Among the different machines, the pomace dryer represents the decisive equipment in the fertilizer making process. While dewatering machines and compost turners start the moisture reduction journey, the pomace dryer ensures final precision. This machine applies controlled hot air flow and uniform drying technology to protect nutrient content while removing excess water. Proper dryer design also prevents over-drying, which could make fertilizer particles brittle and unsuitable for later handling.

When manufacturers adopt a high-quality pomace dryer, the fertilizer production line achieves consistent granule size, smooth pellet surface, and reduced dust generation during packaging or transportation. The dryer also enhances energy efficiency because advanced models recycle heat within the system. By focusing on this equipment, fertilizer producers can secure both cost control and product reliability. For customers who require continuous production, the pomace dryer guarantees stable drying capacity regardless of seasonal changes in raw material moisture levels.

How Can Equipment Selection Shape the Overall Fertilizer Manufacturing System?

Every fertilizer production system depends on the right combination of machinery. A dewatering unit handles the initial removal of water from pomace residues. A composting machine creates a stable organic base for later pellet making. A wet granulator transforms semi-dry pomace compost into uniform fertilizer particles. Finally, the pomace dryer finishes the process by stabilizing moisture content below 10%. Each piece of equipment works together, but only when the dryer maintains accurate control can the final fertilizer product achieve commercial standards.

Producers who value long-term quality must view each stage as part of a connected technology chain. The reliability of the pomace dryer determines the strength of the granule, the shelf life of the fertilizer, and the acceptance rate in the marketplace. For this reason, equipment quality and technology design directly shape the entire fertilizer manufacturing outcome.

Conclusion

Pomace fertilizer production requires systematic water reduction, starting from raw material dewatering and composting, followed by granulation, and ending with precise drying. Fruit pomace, grape pomace, olive pomace, and vegetable pomace all create opportunities for high-value fertilizer manufacturing, but the drying procedure remains the central factor in maintaining quality.

A professional drying equipment manufacturer—Yushunxin—offers advanced pomace dryer machines designed to stabilize fertilizer granules, improve production efficiency, and ensure long-term product stability. With the right technology and equipment combination, fertilizer producers can transform high-moisture pomace waste into reliable organic pellets that satisfy industry demand. You can visit: https://www.fertilizerdryer.com/pomace-drying-machine/