If you’re planning to set up an organic fertilizer production line, selecting the right equipment is the most crucial step for ensuring efficiency, quality, and profitability. Whether you are handling animal manure, crop residues, or food waste, the right machines can transform raw materials into valuable, eco-friendly fertilizers.

In this blog, we’ll walk you through the essential organic fertilizer production equipment and how to choose machines tailored to your production goals.

Why Equipment Choice Matters in Organic Fertilizer Manufacturing

Organic fertilizer granulation line is not just about composting waste—it’s a well-engineered process that involves fermentation, processing, granulation, and packaging. The right equipment can:

-

Boost production efficiency

-

Ensure nutrient retention and microbial survival

-

Lower energy and labor costs

-

Improve product quality and market competitiveness

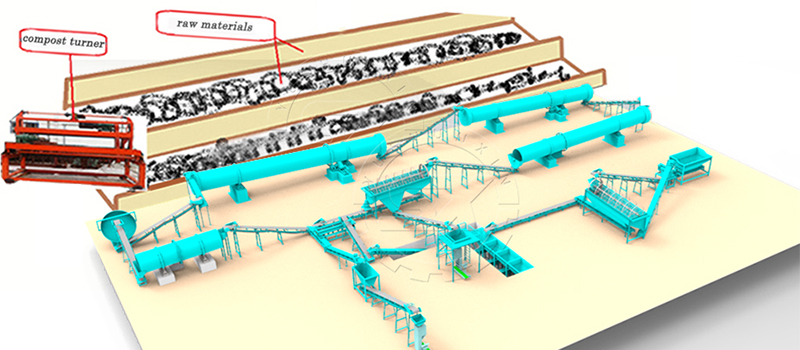

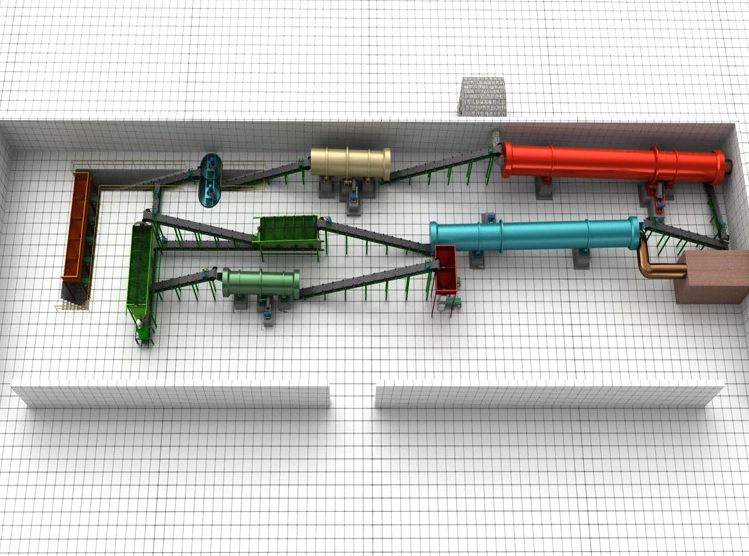

Common Organic Fertilizer Production Equipment

Here’s a breakdown of the core machines used in a typical production line:

1. Composting Machine

-

Types: Windrow compost turner, groove type turner, in-vessel fermenter

-

Purpose: Accelerate aerobic fermentation and remove harmful pathogens

-

Tip: In-vessel fermenters are ideal for odor control and fast processing in urban or indoor settings.

2. Crushing Equipment

-

Example: Vertical crusher, semi-wet crusher

-

Function: Breaks down fermented materials into fine powder

-

Application: Essential before granulation or mixing stages

3. Mixing Machine

-

Type: Horizontal mixer

-

Purpose: Evenly blend organic base material with functional microbial strains or additives

-

Advantage: Ensures consistent fertilizer quality

4. Organic Fertilizer Granulator

-

Types: Disc granulator, rotary drum granulator, extrusion granulator

-

Use: Turns powder into uniform granules for easier storage, transport, and application

-

Note: Wet granulation machines like rotary drum granulators require a drying system.

5. Drying & Cooling System

-

Needed for: Granular fertilizer lines

-

Equipment: Rotary dryer and rotary cooler

-

Purpose: Reduce moisture and harden granules for long-term storage

6. Screening Machine

-

Role: Remove oversize and undersize particles for uniform final products

-

Optional: Return oversized granules to crusher for reprocessing

7. Automatic Packaging Machine

-

Function: Accurately weigh and seal bags

-

Capacity: Available for 25–50 kg bags or bulk packaging

How to Customize Equipment for Your Organic Fertilizer Project?

Every project is different. Here are three factors to consider when configuring your equipment list:

-

Raw Materials

Cow dung, chicken manure, sludge, or biogas residue—each has its own processing needs. -

Product Type

Powdered fertilizer requires fewer machines, while granulated fertilizer needs a complete drying and cooling system. -

Production Scale

From 1 t/h to 20 t/h—we can match the right capacity machines to your output goals. - Click here to get more details !

Why Choose YUSHUNXIN Equipment?

At YUSHUNXIN, we specialize in customized organic fertilizer equipment solutions. Our advantages include:

-

Over 20 years of manufacturing experience

-

Modular equipment design for easy scaling

-

On-site installation and training support

-

Free plant layout and cost estimate

-

Successful projects in over 30 countries

Need Help Building Your Organic Fertilizer Plant?

From composting to granulation, we offer full-process equipment and solutions to match your materials, budget, and local market. Whether you’re starting small or scaling up, our team is ready to assist. Contact us now for a free consultation and quotation: https://www.fertilizerequipmentprice.com/organic-fertilizer-granulation-plant/