With the rapid expansion of poultry farming worldwide, managing chicken manure has become both an environmental challenge and an economic opportunity. Chicken manure fertilizer production, or what many call poultry waste recycling, is an effective way to transform nutrient-rich organic waste into high-quality bio or organic fertilizer.

Why Convert Chicken Manure into Organic Fertilizer

Raw chicken manure is known for its high nitrogen and phosphorus content, but it also contains pathogens, ammonia, and excessive moisture that make direct use unsafe. Through proper poultry manure composting or chicken dung fermentation, these harmful substances can be neutralized, while preserving the essential nutrients for plant growth.

By processing manure into fertilizer granules or powder, farmers not only solve the problem of waste accumulation but also generate sustainable income from what was once a disposal issue.

Key Stages in Chicken Manure Fertilizer Processing

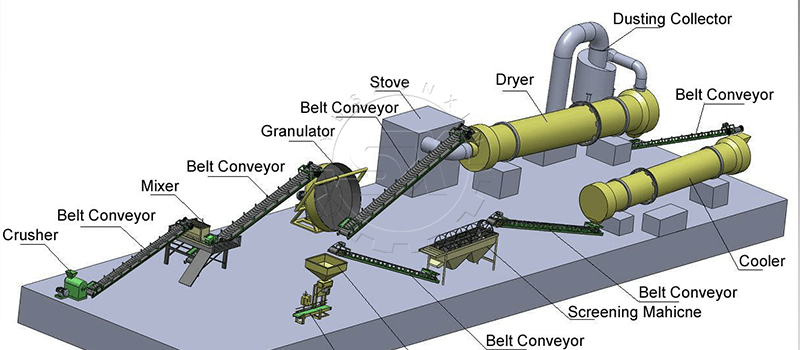

The chicken waste fertilizer manufacturing process typically includes several essential stages:

Fermentation or Composting – Using aerobic composting systems such as windrow turners or fermentation tanks, raw manure is decomposed to eliminate odor and pathogens.

Crushing and Screening – The composted material is crushed into fine powder and screened to remove impurities.

Mixing and Formulation – Nutrients or microbial agents can be added to balance the NPK ratio and improve fertilizer efficiency.

Granulation (Optional) – Some producers choose to make pellets using pan or drum granulators for easier storage and application.

Drying and Packaging – Moisture reduction ensures longer shelf life, while automatic bagging machines enhance output efficiency.

Each step plays a critical role in converting broiler litter or poultry manure into stable, nutrient-rich fertilizer.

Different Scales and Equipment Options in Your Plant

Depending on plant size, chicken manure fertilizer production lines can range from small compost setups for local farms to full-scale poultry waste recycling plants for industrial producers.

Small-scale operators often prefer simple configurations—like a compost turner, crusher, and packing unit—while large facilities may integrate advanced fermentation and granulation systems for continuous production. Click here to get more!

A Sustainable Path Forward

The move toward organic fertilizer from chicken waste reflects a broader shift in agriculture toward circular, eco-friendly systems. It helps farmers reduce chemical input dependence while improving soil fertility and structure over time. If you want to know more, please feel free to contact YUSHUNXIN!

Welcome to visit : https://www.fertilizerequipmentprice.com/20t-per-hour-chicken-manure-fertilizer-production-line/