The demand for organic fertilizer has been steadily increasing. If you’re able to build an efficient production line, it’s likely that you’ll be able to bring in substantial profits. With that said, you should make sure that you take the right approach. Focus on finding the ideal design for your organic fertilizer production line.

Look at Other Successful Plants

Naturally, you want your plant to thrive. If you want great results, why not take a look at other plants that have reached high levels of success? If you examine these plants and look at the design of organic fertilizer production line, you’ll have a clearer picture of what your own plant needs.

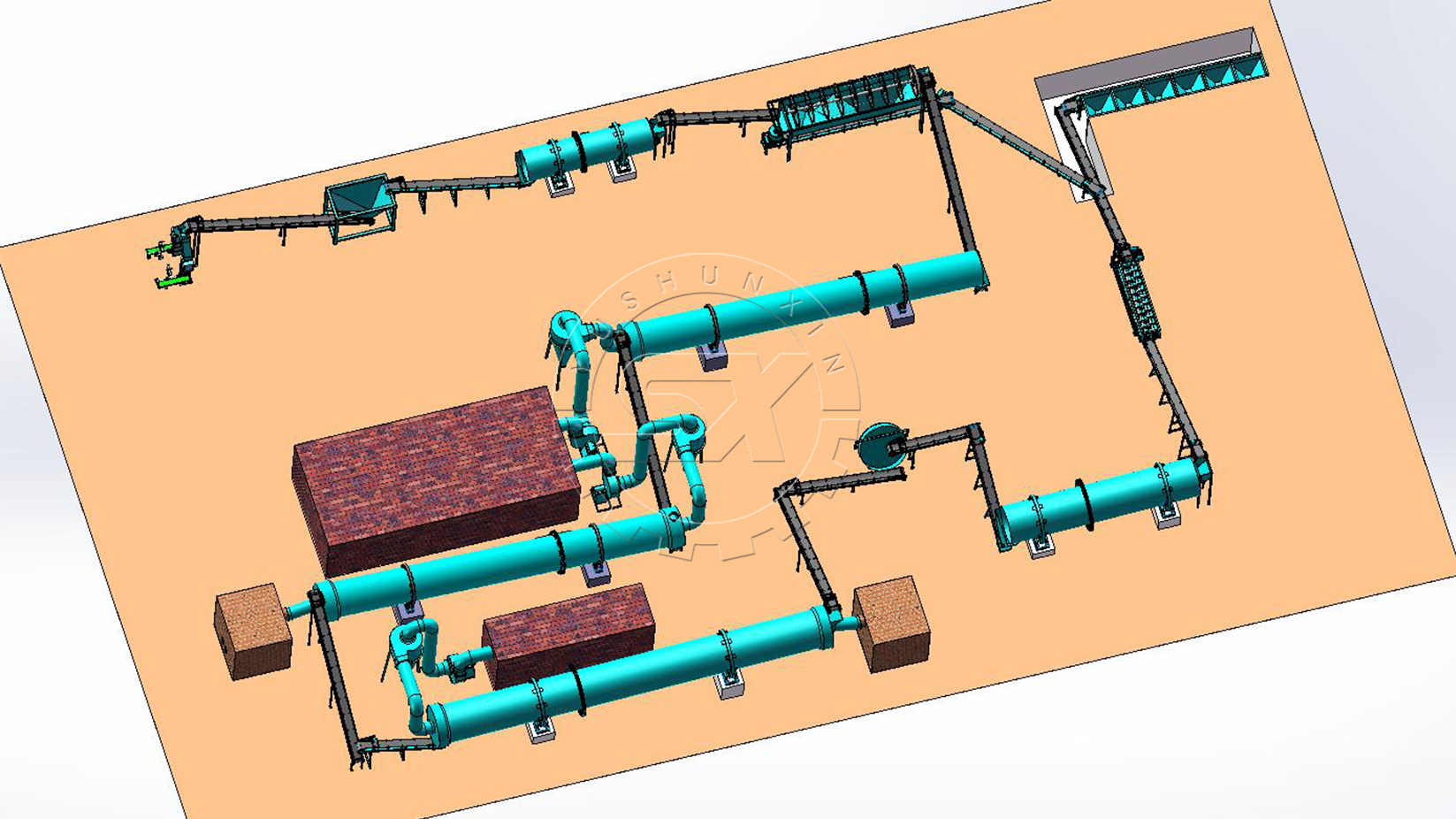

If you don’t have the option of touring a plant in person, you may want to look at video footage of plants. This will allow you to see the equipment that these plants are utilizing, and it will also give you the opportunity to look at the layout of the plant.

Consider the Space That You’ll Be Operating In

While other organic fertilizer plant layouts can be a source of inspiration, the best design for your production line will vary based on the space you’ll be working in. You’ll want to make sure that you use your layout as efficiently as possible.

The amount of space you have will limit the equipment you’re able to invest in. Measure your space carefully and try to use the space you have as efficiently as you possibly can. Make sure that there will be ample space for employees to walk around and examine the equipment as needed.

Find a Vendor That Can Answer Your Questions

The right vendor can provide a great deal of guidance as you search for your ideal organic fertilizer plant. Seek out a vendor that has strong communication skills and is more than willing to answer any questions that you might have.

Your vendor may be able to offer you recommendations and guide you towards equipment that is in line with what you’re looking for. Make sure that you have a way to find out more about the machinery you’re looking at ahead of your purchase.

Decide If Buying a Full Production Line Is the Right Option for You

If you want to make sure that you select equipment that works well together, you may find that purchasing a full organic production line is your best choice. Buying bundled equipment is an easy way to acquire equipment that will work together seamlessly, and it can also help you to find high-quality equipment at a better price.

Look at the bundles available from vendors that you trust. If you feel that you could build a production line with a better design, you should feel free to do so. However, buying a complete production line could be a way for you to save both time and money.

Make sure that you keep all of this advice in mind as you strive to find the ideal design for your organic fertilizer production line. Choose your equipment with care and work to build a fertilizer plant that will exceed your production goals.