Introduction to NPK Fertilizer Production

NPK stands for nitrogen (N), phosphorus (P), and potassium (K), which are the three primary nutrients required for healthy plant growth. Producing NPK fertilizer involves blending these three essential nutrients in specific ratios to meet the nutritional requirements of various crops. A 30 t/h NPK fertilizer production line is a large-scale operation designed to manufacture thousands of tons of fertilizer annually.

Initial Planning and Design

Assessing Nutrient Requirements

Before launching into production, it’s essential to understand the nutrient requirements of the target market. This information will guide the formulation of the NPK blend. The ideal NPK ratio may vary based on soil composition, crop type, and regional agricultural practices.

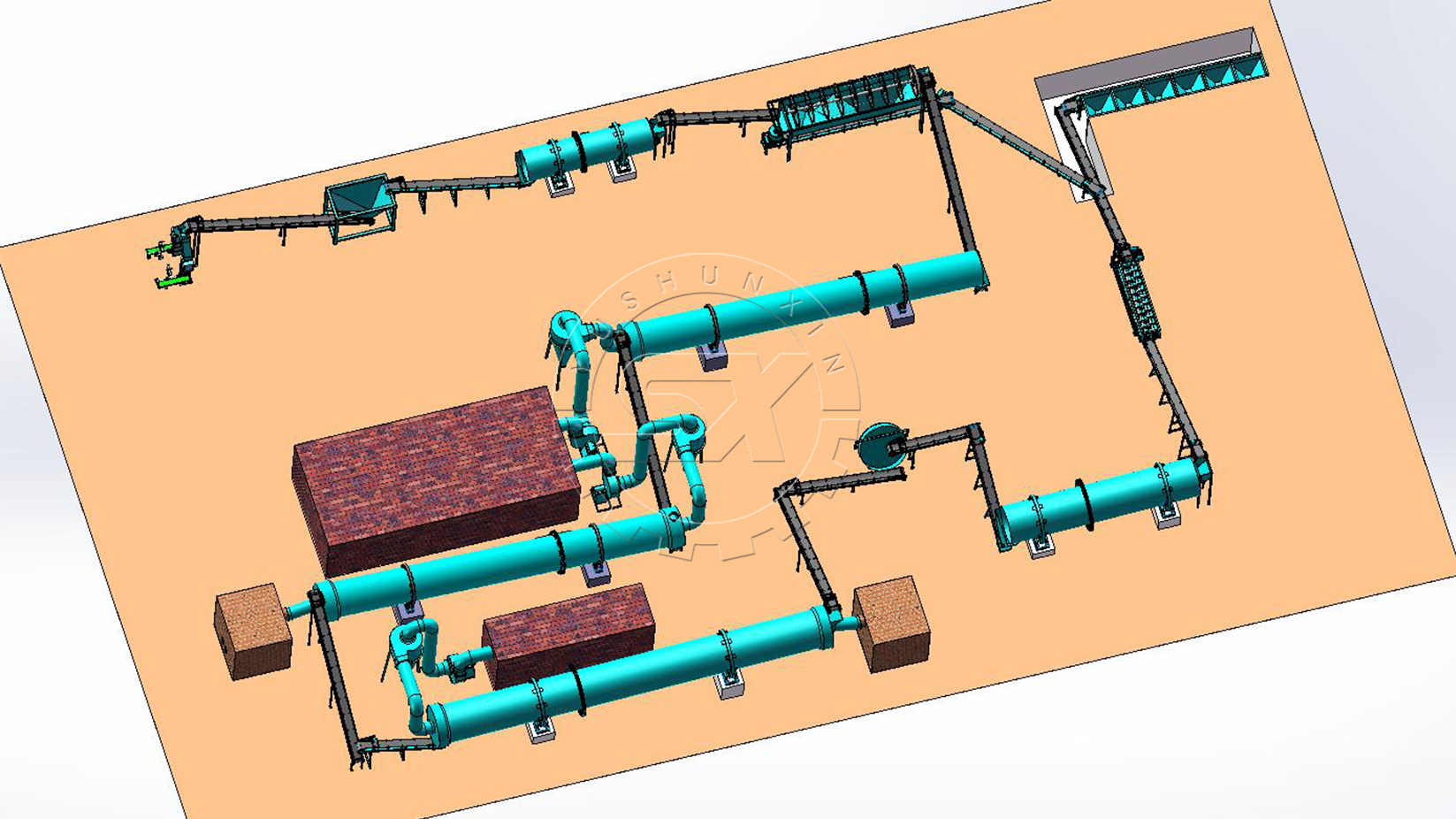

Facility and Equipment Planning

A comprehensive plan for the facility layout is necessary to ensure an efficient production flow. Major equipment for a 30 t/h line includes batching systems, mixers, granulators, dryers, coolers, screening machines, coating machines, and packaging equipment.

Raw Material Procurement

Sourcing Key Ingredients

The primary ingredients for NPK fertilizer are ammonium nitrate, urea, ammonium phosphate, and potassium chloride or potassium sulfate. Securing reliable suppliers of these raw materials is crucial for uninterrupted production.

Storage and Handling

Upon arrival, raw materials must be stored properly to prevent contamination and degradation. Appropriate storage facilities and handling procedures are vital to maintain the integrity of the materials.

Production Process

Batching and Mixing

The first step in production is to batch and mix the raw materials in the correct proportions. Automated batching systems can ensure accuracy and consistency in the mix.

Granulation

Granulation is the process of agglomerating the NPK mixture into pellets. This can be achieved through various methods, such as drum granulation, pan granulation, or extrusion. According to the capacity of 30 t/h, we recommend you to use the rotary drum granulation machines.

Drying and Cooling

After granulation, the pellets are often too moist and must be dried to a specific moisture content. A rotary drum dryer is commonly used for this purpose. The pellets are then cooled to stabilize them and improve storage properties.

Quality Control and Screening

Quality control is essential to ensure the product meets the desired specifications. Screening separates out-of-spec pellets, which can be crushed and recycled back into the production process.

Coating and Finishing

Coating pellets with a protective layer can improve their physical properties, such as reducing dust or enhancing nutrient release profiles. Once coated, the NPK fertilizer is ready for packaging.

Packaging and Distribution

Final Packaging

Packaging options may include bags, totes, or bulk loading, depending on the market requirements. Automated packaging lines can increase efficiency and reduce labor costs.

Logistics and Distribution

A logistics plan is necessary to distribute the final product. This includes transport to warehouses, distribution centers, or directly to customers.

Cost-Effective Production Strategies

Efficiency Optimization

Implementing energy-efficient technologies and optimizing production processes can reduce operating costs and increase profitability.

Waste Reduction

Minimizing waste not only reduces costs but also contributes to environmental sustainability. Recycling in-process waste into the production line is one way to achieve this.

Continuous Improvement

Regularly reviewing and updating production practices can lead to continuous improvements in efficiency and product quality.

Conclusion

Producing 30 t/h of NPK fertilizer is a complex process that requires careful planning, efficient production practices, and a focus on quality control. By understanding each step of the production process and implementing cost-effective strategies, manufacturers can produce a high-quality product that meets the needs of the agricultural sector. And if you want to build a npk fertilizer making line, we can also offer you the best soliution.