Raising chickens can be a rewarding endeavor, providing fresh eggs and meat for your table. However, it also comes with the challenge of managing the waste produced by these feathery friends. Chicken manure is a valuable source of nutrients for plants, but it needs to be properly processed to avoid potential environmental and health issues. One effective method to deal with chicken waste is by using a chicken manure dryer. In this guide, we will explore the benefits of using a chicken manure dryer and provide a step-by-step process on how to use it efficiently.

Benefits of Using a Chicken Manure Dryer

- Nutrient-Rich Fertilizer Production: Chicken manure is an excellent organic fertilizer, rich in nitrogen, phosphorus, and potassium, which are essential nutrients for plant growth. By using a chicken manure dryer, you can convert the wet and potentially harmful waste into a valuable resource that can enhance soil fertility and promote healthier plant growth.

- Odor Reduction: Fresh chicken manure has a pungent odor that can be unpleasant for both you and your neighbors. However, the drying process significantly reduces the moisture content, leading to a reduction in odor. This makes the dried manure more manageable and less bothersome for nearby residents.

- Pathogen Elimination: Raw chicken manure can contain harmful pathogens and bacteria that may pose health risks. Drying the manure at high temperatures helps eliminate these pathogens, making the fertilizer safer for agricultural use.

- Improved Storage and Handling: Dried chicken manure has a longer shelf life compared to the wet counterpart, allowing for easier storage and transportation. Additionally, its reduced weight makes handling and spreading the fertilizer more convenient.

Step-by-Step Guide on How to Use a Chicken Manure Dryer

Step 1: Collection and Preparation Gather the chicken manure from the coop and remove any large debris, such as feathers and straw. For the best results, use a manure scraper to collect the waste daily. Proper collection ensures that the manure is as pure as possible for the drying process.

Step 2: Choose the Right Dryer There are various types of chicken manure dryers available on the market, including drum dryers, paddle dryers, and fluidized bed dryers. Each type has its advantages and disadvantages, so consider factors like the amount of waste generated, energy efficiency, and available space before making your choice. SX chicken waste dryer can meet all your requirements.

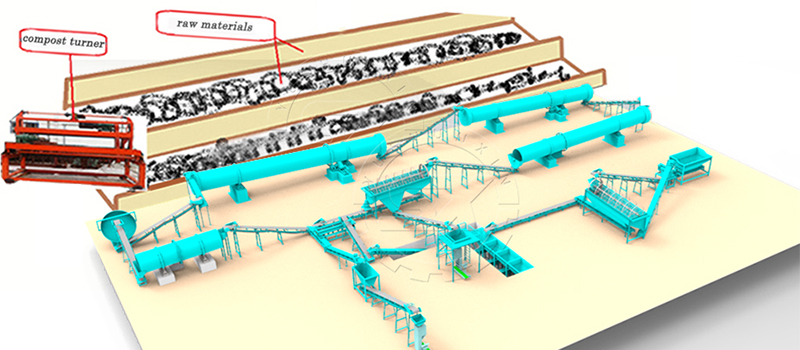

Step 3: Pre-treatment (Optional) Some dryers may require pre-treatment of the chicken manure, depending on the specific type of dryer you are using. Pre-treatment could involve processes like chicken manure composting or shredding the waste to ensure more effective and uniform drying.

Step 4: Load the Dryer Once your chicken manure is prepared, load it into the dryer according to the manufacturer’s guidelines. Avoid overloading the dryer, as this can lead to uneven drying and less efficient results.

Step 5: Drying Process Turn on the dryer and set it to the appropriate temperature and drying time. The drying process will vary depending on the type of dryer, but generally, hot air is circulated through the manure to evaporate the moisture. This step may take several hours to complete. Click here to get more detailed information.

Step 6: Cool and Store the Dried Manure After the drying process is complete, allow the dried manure to cool down before handling it. Once cooled, store the dried manure in a cool, dry place in airtight containers or bags to preserve its nutrient content.

Step 7: Application as Fertilizer The dried chicken manure is now ready to be used as an organic fertilizer. Apply it to your garden or agricultural fields at the recommended rates, considering the nutrient needs of the specific plants you are growing.

Conclusion

By utilizing a chicken manure dryer, you can effectively manage chicken waste, turning it into a valuable resource for your plants while reducing odors and eliminating harmful pathogens. Remember to follow the proper steps in the drying process to ensure the production of high-quality, nutrient-rich fertilizer. Properly managed chicken waste not only benefits your garden but also contributes to a more sustainable and environmentally friendly farming practice. If you are interested in chicken manure dryer, you can visit https://www.fertilizerproductionproject.com/chicken-manure-dryer/.